Forum Replies Created

-

AuthorPosts

-

February 18, 2015 at 1:35 am #416

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Thanks for that

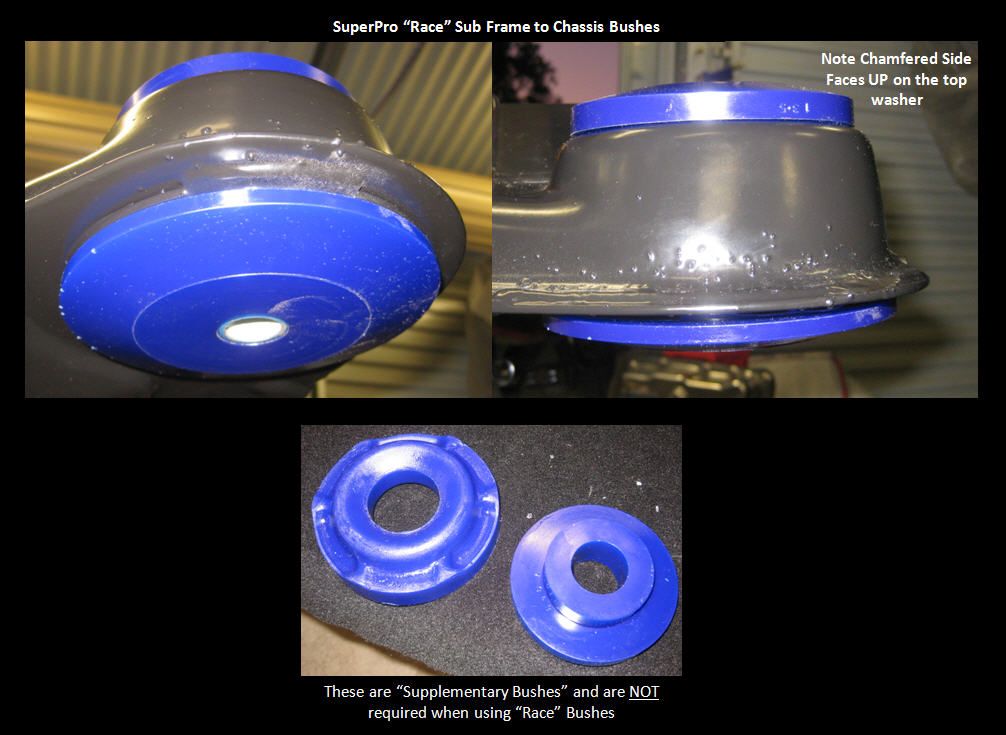

Have got the SuperPro bush issue sorted, thought I would put up a picture for future reference for posterity.

I am using the Race version of the sub frame bushes. The quote I had was “the next stiffest thing you could do would be weld the sub frame to the car”:)

First of all no information comes as to which way up they the top washer goes. A call to the SuperPro tech dept had them guessing too, the kindly phoned back a little later and advised the chamfered (sloped) side faces up.

Second thing was i was supplied “Supplementary Washers” I couldn’t fathom where or how they fitted. Again no diagrams. Bit of back and forth then turns out these are used when using regular style bushes to fill the voids to make it stiffer. Since the Race are a solid lump of urethane they aren’t required.

Diagram below

February 18, 2015 at 1:34 am #415

February 18, 2015 at 1:34 am #415

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Not a bad day today, got a fair bit done on the rear end, had bit of a moment putting the VY handbrake mechanism together as I accidentally mixed up two small parts from the VR and VY but once I worked it out I was ok. Not really photo material yet.

Couldn’t help myself though and did a quick fit up of the gearbox to the engine, I haven’t fitted the starter swap kit or anything so just to the a rough idea how it looks.

And just a random of the shed

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:33 am #414

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Really happy with how this turned out.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:32 am #413

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777 February 18, 2015 at 1:32 am #412

February 18, 2015 at 1:32 am #412

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well had a win, been sort of holding off painting the under-body where the sub frame sits as I thought it would be difficult, but got stuck into it this afternoon and actually was pretty easy. Spent bloody ages masking up, and probably went a little overboard, the textured under-body coating doesn’t seem to drift like a normal aerosol can. Really happy with it, although I thought it may have been a little more textured to match the rest Frank has done. Not sure its worth worrying about though. Not sure if other brands (I used Motorspray Textured Under-body Coating) are any more textured?? Anyhow, looks great I think.

February 18, 2015 at 1:31 am #411

February 18, 2015 at 1:31 am #411

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Had a good look at the sub frame, and really like the suggestion by Marzella (thanks

) to add a member that ties the top and bottom halves together which also is in exactly the right plane to take the torque. Thats why this forum rocks.

) to add a member that ties the top and bottom halves together which also is in exactly the right plane to take the torque. Thats why this forum rocks.So this morning got stuck into it. I plan on using a piece of 10mm flat mild steel, welded top and bottom. Had to hunt around for something 10mm to use as a guide, ended up getting a piece of scrap timber planed down. Dont want to bore everyone with a 1001 pictures, but the basic process is below.

All good to go now, going to take to a welder I have used before, don’t trust my own on something like this, bit worried about distorting it too. Will post up once ts all done and all powder coated up.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:31 am #410

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

This is what I am planning with the strengthening of the sub frame. Interested in peoples thoughts. Thinking of 5 or 6mm plate. The idea is that the welding guys can use the cardboard as templates for the plate.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:30 am #409

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well got the hand brake tear down done this week end. Thought I would take some pics and describe the job.

First of all, anyone who says its an easy job has either never actually done it or must have had a lot of luck :). It is a very tedious and awkward job. Bear in mind the removal and disassembly process has to be done 4 times, twice for the VR arms, then twice for the VZ to get the mechanism off them.

I have a a press, but holding the arms in place whilst pressing everything out is quite frankly a pain in the butt, they are quite heavy and awkwardly shaped. Admittedly I am doing all this on my own, someone to hold the arms whilst doing stuff would have made it a lot easier.

Here some pics and description, probably could have taken a couple more but anyhow, hopefully helps someone if they do it themselves.

Step 1

First step is to remove the Trunion Flange Nut. It is VERY tight, I sprayed it with WD40 for a few days morning and night, then used the longest breaker bar I have and had a tube through the wheel studs to stop it turning.Step 2

I then used a puller to remove the Trunion Flange. Interestingly on the late model arms it came off very easily, on the VR it was much tighter on the splines.Step 3

There are two bolts that hold the hand brake mechanism on, remove these and the cast mechanism, I cleaned it up after with a wire wheel and it looks like new now.Step 4

There are also two star bit bolts that hold the brake backing plate to the trailing arm that need to be removed.Step 5

I then set it up in the press and pressed out the Trunion. It was bloody awkward and hard to hold, and my press is 20T and used every bit of it to get them out, got them in the end though. Was too difficult to hold it and take a picture.Step 6

This then exposed a large circlip on the wheel side of the hub that retains the bearing. It’s a big sucker and very difficult to get out. I got one out OK, but the other I bent getting out so will have to pick up a spare. Forgot to take a pic of that bit.Step 7

Once the circlip is removed its back into the press again to press out the bearing, it came out pretty easily.You are then left with the parts, you can see the inner race of the bearing stayed on the shaft. On the right you can see the circlip groove where the big bearing retaining circlip fits.

Step 8

I then used a pullet to remove the inner race.Step 9

Then I removed the backing plate, and used a cut off wheel in my 4″ grinder to cut off the outer lip as it fouls the larger discs i am using.I then clamped it flat and took it down with a grinding wheel .

Lastly I finished it off nice and smooth with a die grinder and hand file and sand paper.

I am going to get it powder coated with all the other suspension bits, that wont be for a while so I thought I would paint it just to stop it all rusting.

This shows the before and after

As I say, bugger of a job really, but at least its done, I will order some new bearings and the circlip, get it all powder coated, reassemble it all and it will be good to go.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:29 am #408

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Got the rear end out tonight. Fairly straight forward, although one mistake I made was I didn’t have an M15 6 sided socket so I used a std 12 sider with my rattle gun and rounded the head off (my fault for being impatient). Went to total tools today and bought a 6 sided and did it by hand with a long socket bar and got it off, glad, wasn’t looking forward to the alternative…have also contacted a guru I know re the diff ratio and waiting to hear back.

Pics of the rear end, surprisingly given how I used to drive it the sub frame isn’t cracked. My car had self leveling suspension, so I carefully removed the pump assy and will put it aside so I could refit it if I ever wanted.

Years ago when I fitted the lowered springs I think they did some nolathane sub frame to body bushes, tbh has forgotten about that. Time for a big clean up on the week end then start the disassembly.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:28 am #407

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well that didn’t take as long as I thought. Was dreading putting the back seats in but once I worked out the trick was to remove the head rest tube, fit the bracket, then seat, then refit the tube was pretty easy. Gotta say I am stoked with how the interior has turned out, I think its the best its ever looked since I have owned it. There’s a couple of small trim bits I will pick up as I come across them, have assembled the shifter mechanism stock until I work out which way I want to go later in the build. Am thinking maybe pro ratchet but mounted a bit stealthy so its all hidden under the stock console, but that can wait for later.

But that’s all for now. Up on the hoist she goes now for the oily bits, happy days

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:28 am #406

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Woo Hoo, father Xmas has come early. The brakes arrived today, little bit of a mess up getting them that my lad sorted through his work, upshot was they gave me a pretty healthy discount. Look awesome in the flesh. The red calipers were special order, seeing them now really glad I went red, should look nice against the dark car colour.

Dead right about the 12 bolt, it’s the GM equiv to a 9″, It’s 8.875″, should be bullet proof. Will pm you later Chris, too excited about th brakes right now

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:27 am #405

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

OK, bit of an update. I have spoken to a lot of people about various options, and everyone of them has its pluses and minuses. It really came down to the 9″, a built M80, or the Harrop 12 Bolt. I pretty early on decided to not go down the build my own route. I think if I wasn’t going the 454 I might have, but I just think it needs to be spot on and I am just not sure this is the first diff I should attempt to build.

In the end I have gone for this with a Detroit Locker and 3.50:1 ratio.

I know everyone is different and really some of this came down to a p#$%ing contest as all 3 could have worked, but for me these are the reasons;

1. Its a direct bolt in replacement for an IRS VR

2. Its an Australian product sold locally

3. Its not Ford

4. Harrop, although expensive, are recognised as top quality

5. Its available in a full range of ratios

6. The help, advice and service I have received by Mark at Harrop has been excellent.

7. The Detroit Locker is bullet proof, tried and true, and perfect for what I have planned.-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:27 am #404

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well fitted the finished wheel today, extremely happy with the results. Thought I may as well post some pics, I followed the process CPC posted earlier with the guy on the Brock forum so won’t go into too much detail. Only thing is I didn’t spray at all I used cloths. Personaly I didn’t want it dead smooth, I wanted to keep some of the battle scars but freshen it up. It would be really easy to make it almost like plastic smooth is ya wanted. Some photos

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:26 am #403

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well thought I would post this for interests sake. I have just received the 3D scan back of the existing wheel. Interesting its so accurate its picked up the distortion in the rim etc. Its accurate to about 0.1mm. Next step is some 3D CAD manipulation to get what I want which is going to be fairly complex, at least I can do that myself otherwise it would blow the cost of the rims out of the water.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:26 am #402

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well I sort of want this thread to be accurate and hopefully a source of some info for people about originality for the VR Senators. A guy has kindly replied back on the HSV forum, and I trust these guys they are very knowledgeable.

For the record, and to finish this off, below is a picture I have made up showing the two different styles of steering wheel, to be honest without someone pointing it out not sure I would have noticed unless I got them side by side, and unless your really into it, it probably doesn’t really matter.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:25 am #401

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Another excellent day today, got lots done, may not look like much but these trim jobs are pretty fiddly, especially as I am paranoid about scratching anything. Went down again to U-Pull-It (my new fave place) and picked up a rear passenger electric window mechanism, drilled out the rivets, actually pretty easy job. Took my test cable and went over to their battery stand and hooked it up to make sure it worked and was quiet, got a few funny looks. Fitted that up, bit fiddly but was patient, used small size gutter bolts as they have a nice low profile head and bolted it in rather than rivet in case I need to get at it again.

Also picked up the missing trim for the passenger rear door. Got all the external trim pieces fitted, also all the door rubbers. Smothering them in WD40 makes them pretty easy to fit, whilst at UPI also got some of the small black plastic rivet plugs for the ends of the rubbers that anchor them.

Then got stuck into cleaning the interior and it came up great, think I may have to ring CPC and chat to him about how to bring the steering wheel back to life. Thoroughly cleaned the seat belts etc. with warm soapy water to get rid of any of the dust and crap form painting. Next will be fitting the carpet, then bringing back the interior and cleaning it and fitting it, then pretty much its up on the hoist again for the oily bits.

Here’s a few random pics in no particular order.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:24 am #400

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

OK, have done a bit of measuring and playing with the rear wheels, widths and offsets. Note this is on my car which is a 1993 VR Senator, I have had the guards rolled and also the inner portion above the guard relived a little as well whilst they were preparing it for paint. I am pretty sure they were based on a Berlina, with IRS. Other models etc. may be different.

First thing I did was make up a wheel mock up pattern and clamped to a steel rim I had. I made the external diameter the same as the original Senator wheel which was 650mm, I started off the template at 295mm wide.

I then put the car up, and removed the spring so that I could jack the wheel up and down through its travel from maximum to minimum so I could check clearance.

I then played around and moved the pattern in and out, and checked where it would foul. There are 4 main areas below I looked at.

Interestingly, I had heard, and expected that I would need to relieve the trailing arm as it would here first, it doesn’t, the area it hits first is the inner guard area “B” The shock (C) and rear of the arch (D) are also relatively well clear.

This is area A on the trailing arm

So I set the template and put a 5mm drill bit between the area B and the template, I figured 5mm was about as close as I would want to. I then went around and measured the others,

So the clearances were A=12mm, B = 5mm, C=20mm, D=22mm.

Then having set the inner position I started with the template at 295mm wide. It fouled the outside of the guard, I then trimmed it back and the widest I could get was 285mm.

So the widest tyre I can currently fit = 285mm

I then measured the offset on the steel rim, which as I understand it is the full rim width / 2 less the distance from the edge to the hub mount face. That worked out to be 45mm. Tbh I have no idea what model Commodore this wheel is off. I then measured the template relative to the steel wheel. I then laid it out on paper, the calculations are below,

I would have done it a bit neater on CAD but wanted to do it now.

From it I have worked out that the offset I need is 30.5mm, or make it 30mm.

So for my car, the widest possible tyres I can fit are 285mm, with an offset of 30mm.

I think it would be possible to go a little wider, maybe 295, but you would need to “massage” area B in a bit, and it may be possible to tweak camber. Interesting day.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:23 am #399

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Great day today, she’s back :) Flat bed brought it over about 10. Got it in the shed, just for giggles have fitted the new rear lights and number plate. Also have put the two refurbed wheels on the right side to see what it will look like. Tomorrow will start to play around with the rear wheels to get a feel for how wide I can go, good times…

Not the best quality photos, was raining today so couldn’t get her out and wash her as well as I would have liked, but looking great.

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

February 18, 2015 at 1:22 am #398

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777 February 18, 2015 at 1:21 am #397

February 18, 2015 at 1:21 am #397

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well I think i jizzed my pants ha ha, finally colour, not bad just off the gun, so happy so far..

-

This reply was modified 7 years, 3 months ago by

VRSenator065.

VRSenator065.

-

AuthorPosts