Forum Replies Created

-

AuthorPosts

-

April 14, 2020 at 12:15 pm #31892

looks awesome mate. gotta love got bang for buck of an S475

April 14, 2020 at 12:05 pm #31891Another update. Covid kicked my ass, so i sold off my old 5L setup. Progress will probably slow up til the end of the year but ive got plenty of little jobs to do in the meantime.

Mounted up my intercooler (aeroflow 600x300x100) by making up some simple steel brackets, used nutserts for easy install. Has 4 couplers in the system. 90* 4-3 off TB, 90* 3″ on cooler, 76* 3″ on the other side to 3.5-3 straight into the turbo. Will be using sprung tensioned cooler clamps that we use on trucks.

Gave AC tig welding a crack for my alloy cooler piping, welds arent too bad.

Made a DIY “bead roller” consisting of vice grips, an exhaust clamp and a washer. works really well and saved me $400. I also modified my compressor housing by grinding off the vband to a bulge so a 3.5″ silicone coupler slides over, keeps it nice and simple. I also painted my compressor housing and intercooler piping satin black.

In those photos you can also see that i fit a fenix stealth radiator and am trying a bf-fg simple thermo fan this time around, just need to finish making some mounts for the top of it. Radiators a VL rad with a cut down top hose and a Gauge adapter for the steam port (ill be running AN fittings to all the steam ports), just need to figure out what bottom hose to use.

If anyone knows of a super slim 5″ pod filter let me know. Im gonna be running an aeroflow turbo guard for fun duties, but would really like a filter for cruising around. Between turbo and rad support is around 80mm, so i need a filter that overall (inculding flange) is 100mm, without trimming the lip. Closest ive found is k&n do a 130mm long one.

March 25, 2020 at 5:31 pm #31722Thanks man. Been following your builds for years now. Always loved what you’ve done.

im mostly self taught. Have had some guidance from boilermakers at work but other than that just time. I’d never touched a tig welder before. Having a lot of fun just practicing, watching videos and learning the art. My welds aren’t the prettiest but they do the job haha.

all I can say is pick up a welder and some scrap steel and give it a crack.

March 25, 2020 at 12:27 pm #31717bit of an update.

turbo and wastegate arrived, as well as my dump pipe flange.

Borgwarner S475 T6 and turbosmart 50mm GenV Progate.

Made the rest of my turbo manifolds, bought a TIG welder so been learning that process.

Dummy fit, Mounted up turbo, going to have to run elec power steering because my wastegate will be off the exhaust housing.

dont have any photos of it but just bought my intercooler (aeroflow 600x300x100), slight bumper trim and it fits quite nice. have a fait bit of room above it to fit a slim oil cooler and power steering cooler.

took the old daily patrol out to cruiser park too, so may aswell throw that photo in here.

-

This reply was modified 4 years, 9 months ago by

moodybluebob.

moodybluebob.

September 25, 2019 at 9:13 am #29865As a litte bonus, here’s my daily driver GQ that i painted myself in my shed. Colour is toyota beige.

September 25, 2019 at 9:07 am #29864

September 25, 2019 at 9:07 am #29864Now…

here’s where things get a bit interesting.

Have always wanted more power, the 5L was fun, sounded tough and has been reliable for the last 5 years or so. I was told by many people it sounds like a fast car, but it isnt haha. I considered bolting a charger to the 5L, but then i found a well priced LS conversion for sale on marketplace, which turned out to be a member on here, and just bit the bullet.

Soooo here’s the planned new direction on my build.

SBE LS1 (Ring gaps, Bearings, Studs, full send)

VCM16 cam (springs etc)

Sump already has an ASR baffle

Borgwarner S475 75/88 T6

T56 (will probably blow it up, contemplating dog set)

E85

haltech elite 950, harness and racepak dashthat’s the rough idea anyway.

last photo of the 5L in the car, will miss the exhaust note thats for sure. Pretty stoked on this engine too, built all myself as a 2nd year apprentice, copped and absolute flogging or 5 years and still runs mint. Plans for this motor are to live on in another 2nd gen that my dad will be building.

Engine out, empty (and very dirty) bay.

As quicky as the 5L was out, the LS was in. just engine sitting in there. Bought the entire conversion, so everything just fits, which is great. alternator clearance an sump clearance are great with no mods.

Im proud to say that i give everything a go myself, being a diesel mechanic makes it alot easier than most. Im by no means a fabricator, but im going to do everything myself. I figure the only way to learn new skills is to give it a crack yourself.

So i began making my own 4 into 1 turbo manifolds. They are make out of 40NB buttweld bends, sourced locally from MTQ and Blackwoods. Flanges were purchased from Design fab in ipswich. Great to deal with.

Passengers side tacked up

Drivers side tacked up

Plently of clearance between the manifolds, body and brake lines.

Passenger side all welded up, would have been better with a tig welder, but i only have a mig at the moment, need to clean a few up and check for leaks, but overall happy with the outcome.

Waiting on my turbo now to figure out placement and start making the crossover and T6 flange mount out of 50NB. once they’re completed ill paint then with heatproof paint and wrap then with lava wrap. Then start making dump pipe and cooler piping.

the plan is the have the engine in there for mock up, ill fabricate everything, then pull it all out, rebuild engine and box then everything can slot back in nicely.

September 25, 2019 at 8:34 am #29861oh man…

It’s been a while since i’ve been on here. This will be a bit of a recap post following on from my dyno tune since most of my images are gone.

Had some fun with it for a few years. track days, drifting, drags & plenty of meets.

Destroyed a throw-out bearing at QR, kept throwing belts at lakeside

Wanted a change of rims, so found some VE calais wheels cheap, painted them grey. rocked that for a bit.

May aswell throw in a photo of the interior too since i never really did. Vp calais international interior, devonish seats, genuine momo wheel, lvl3 dash, elec windows, all done by myself. planning on retrimming seats next year.

Life got busy, bought a house, built a shed, just drove this thing to work on fridays. Wanted a tougher look, so cut a speed hole in my bonnet and threw some 20″ GTS wheels, and got some plates for the car, cause you know, it’s slow as.

and a sneaky video of it full noise at lakeside

-

This reply was modified 5 years, 3 months ago by

moodybluebob.

moodybluebob.

-

This reply was modified 5 years, 3 months ago by

moodybluebob.

moodybluebob.

June 23, 2016 at 7:49 pm #17926thanks mate!

Still out enjoying this thing, need to touch the tune up a bit but apart from that loving it. Getting the bug to chase some HP now, but will have to wait for a while. Still having fun so that’s the main thing.

June 9, 2016 at 8:32 pm #17684

June 9, 2016 at 8:32 pm #17684ohh man i remember this thing!

May 31, 2016 at 6:23 pm #17391Pretty slow on the old updates. Ended up putting a spool in a 3.45 diff gears, took over a month because i got severely knocked out in a soccer game and ended up with 6 stitches next to my eye, impared vision and concussion for about 2 weeks, so had to take it easy for a while. back in the swing of things now though.

Diff gears have completely changed the car. Soo much more responsive and sits at just over 2000rpm at 100, which cuts out all drone the exhaust has. Celebrated my taking it to a local downshift meet, not really the scene to take a older commodore but good to take it for a bit of a drive with my old man for his birthday, Car’s now been in our family for 21 years.

Just gonna cruise around an enjoy it for a little now, gonna get a retune now ive sorted out the throttle body issue, but will probably change out to an edelbrock throttle body before the retune.

April 5, 2016 at 8:33 pm #15439Didnt even realise but i had a race against you yesterday at torque time, now i know why you beat me haha. how do you rate the auto lokka now after having it for a while? is the backlash noticable at all? still tossing up whether to put one in my VN or not.

Yeah we had a couple of good races. The VN sounds so tough!!

I still rate the lokka, does the job i need it to do perfectly. Backlash can be noticable at times but only in tight carparks. Im the sort of person that will deal with most things if it meets a purpose, but if you’re keen you can take her for a test drive to test the lokka out.<span style=”line-height: 1.5;”>

I still rate the lokka, does the job i need it to do perfectly. Backlash can be noticable at times but only in tight carparks. Im the sort of person that will deal with most things if it meets a purpose, but if you’re keen you can take her for a test drive to test the lokka out.<span style=”line-height: 1.5;”></span>

Haha thanks man. Sounds the part just need some more grunt haha. Yeha just still not sure what to run. Was even considering a minispool but still thinking about the locker too. thanks man, wouldnt mind just coming for a passenger ride and seeing how it is in car.

Car looked the goods in that matsuri video too, bummed i couldnt go.

March 13, 2016 at 6:31 pm #15013had its first track day at qr on the weekend. car went awesome. Makes me realise it isnt a quick car haha, but had fun cruising around the track. really need to sort diff gears and get both wheels spinning now, then probably save up for a charger.

March 13, 2016 at 6:26 pm #15012

March 13, 2016 at 6:26 pm #15012Didnt even realise but i had a race against you yesterday at torque time, now i know why you beat me haha. how do you rate the auto lokka now after having it for a while? is the backlash noticable at all? still tossing up whether to put one in my VN or not.

February 23, 2016 at 8:02 pm #14431Really need to update this more often. Got my gauges all sorted. Really happy with how it turned out, put green LED’s in them and at night they look awesome, not too bright and easy to read.

Also installed a sandwich plate and oil cooler setup. I plan on doing track days/skidpan days so figured i’d do it with the sandwich plate. Aeroflow sandwich plate and oil cooler, running -8 line that we use on kenworths at work. (have since secured the lines together with double zipties)

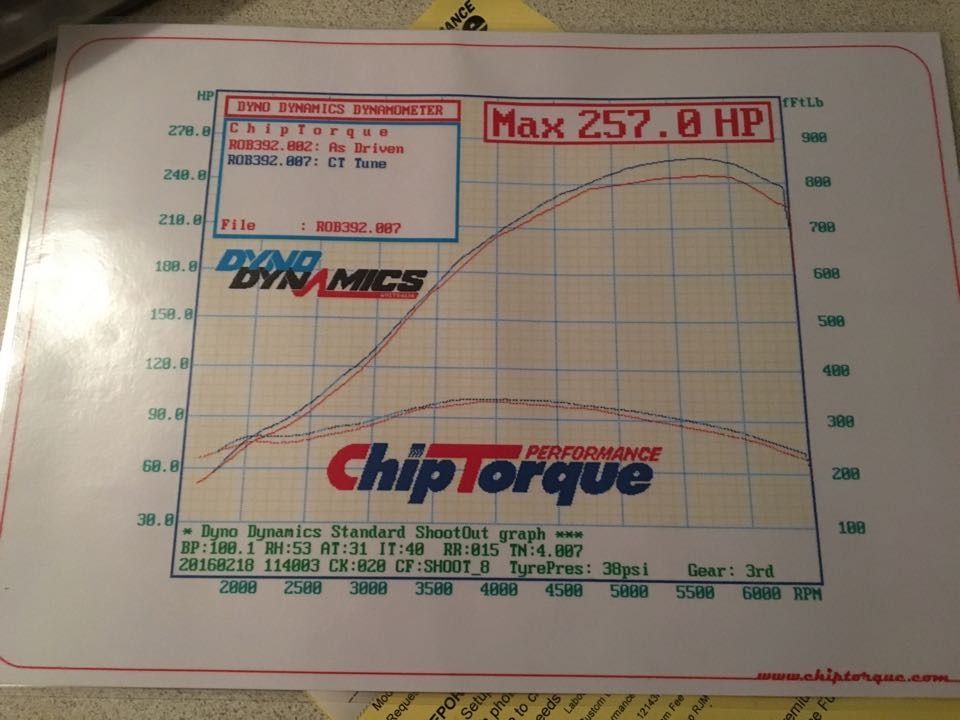

Recently got the car dyno tuned as well. Decided to go with chiptorque down the coast. Was extremely happy with their work, they also got onto proflow (VPW) for me to sort out my tps fault. Basically there was no preload on the tps with the 4bbl, and there was no adjustment at all. They have agreed to replace my throttle body with the revised version that allows for adjustment. So just waiting on that then i can enjoy it for a while. Next on the cards is sorting my diff out. sussed out the auto locker route and i’ve decided against it after reading a few things about them. But not bad power for the old 5L, considering all the work was done myself. Keen to see what it would do down the quarter now aswell.

And to finish off, just a nice shot after washing it in my driveway.

-

This reply was modified 8 years, 10 months ago by

moodybluebob.

moodybluebob.

January 9, 2016 at 9:42 am #13144This reply has been reported for inappropriate content.

keen to see this thing going! god clean donor to work with too!

January 8, 2016 at 7:07 pm #13135Couple of ways you could do it, but remember I don’t have a knob in front of me. The pro ratchet is 1/2-20 which is 12.7 OD, the T5 is M10 so 10mm OD. You could potentially re-drill the knob and tap it 1/2-20. Or you could turn up an adapter that had a male spigot at M10, and a female bore 1/2-20. That would raise the knob up though by the length of the ratchet thread, but tbh the shift is a little firm for my liking anyway so it would give you more leverage so make less effort to operate the shifter. And you could, if the shifter mechanism was out, either turn down the thread on the end of the shifter and re cut the thread as M10, or cut off the thread altogether and if it isn’t hardened drill it, tap it and screw in a stud. Or if its hardened weld on an new M10 threaded section, but that would stuff up the chrome. Prob other ways too.

I drilled out and tapped the T5 gearknob to suit my cube short shifter as the thread was different. is solid as and doesnt twist at all.

Also keen to see how these go price wise. reckon if would look good in my VN

December 27, 2015 at 10:00 pm #12750

December 27, 2015 at 10:00 pm #12750Got it off ebay i think. Its just its not the easiest place to look across too, so the angle does help a little.

Ah yeah cool ill have a look around if this doesnt work out. from sitting in the car it doesnt feel too bad (im 6’6″ so i sit pretty far back) but will just have to see how it goes.

December 27, 2015 at 9:36 pm #12747If its not too late, maybe consider a staggered plate so the guages angle toward you a little. Just a thought.

I only made this out of like 3mm mdf, just to get an idea of what it looks like. What plate did you buy? i remember seeing it in your thread somewhere.

Im a fan of the A pillar or you can do what i did run it in the aircon vent for something different. The centre console seems to be the best place for multiple gauges.

Yeah i like the A pillar look. easy to see too. was even considering keeping oil temp/pressure on the pillar and putting a phantom clock in the middle, but $150 for a clock is about rediculous haha.

December 27, 2015 at 8:56 pm #12738This is what it looked like before. I didnt mind it. everything was in my field of view, but just didnt look good enough.

And here’s what im doing now. Water temp and Engine oil temp. (obviously a old gauge in the middle)

In the middle of those two will be a volt gauge, then will be moving oil pressure to probably on top of the steering column in the centre. or will just leave oil pressure on the pillar.

December 27, 2015 at 2:41 pm #12726Its a clean looking car mate. What plans have you got for the diff upgrade?

Thanks mate, appreciate that.

eventually when time and money permits om going to go an autolocker. I’ve got 3.45:1 diff gears here already and a bearing kit, just need to purchase the auto locker. Couldnt justify the cost of a tru trac.

Bought some new gauges for it today as the speco water temp gauge is already reading incorrectly (tried a new sender and no dice) so went for the autometer Phantom gauges. Suits the car i think. going to install them either today or tomrrow.

-

This reply was modified 4 years, 9 months ago by

-

AuthorPosts