Forum Replies Created

-

AuthorPosts

-

November 15, 2015 at 4:16 pm #11310

Budget sets the precidence.

November 14, 2015 at 6:25 pm #11290Yeah his work is 2nd to non. Totally disagree those rims with a few inches of dish on the back would not only looks ACE but it would have to be the only set in the country.

November 14, 2015 at 6:22 pm #11289Mods look good Gary. But I’m confused on how moving the lever makes it any different? Is it simply to save u cutting a slot into the console?

November 14, 2015 at 11:35 am #11278IMO. It looks perfect as is. To low and walls will make it look tacky.

Never reaslised this had a blower on a detailed bay. Looks awsome

November 14, 2015 at 9:55 am #11274The LSR range have some really nice grinds. Should boogie with that. Does it need fly cuts?

November 14, 2015 at 8:15 am #11270https://www.facebook.com/All-Aluminium-Welding-121184927956142/

The rims your running now with dish on the back would look porn.

November 13, 2015 at 2:57 pm #11250Link?

November 13, 2015 at 2:48 pm #11247My theory is that as long as there is some coolant in the system and no airlock in the bottom hose it (the water pump) will continue to suck coolant from the radiator and force it into the engine so it (the engine) won’t show a major temperature fluctuation until all the coolant is lost in which case by the time you notice it will probably to late anyway. In reality, how often do you notice a change in engine temperature? How often do you check the gauge whilst you drive? If you want a 100% fool proof method you really need to set up a bright warning light that illuminates at a set temp. A much better option would be a low coolant sensor but Holden’s have never had such a thing unfortunately.

i notice the change all the time. Something I always checked up on.

I could actaully notice the difference between 160-190F on the factory gauge also.

It a personal thing on what u would like. TBH if you have an autometer gauge which is already giving you an ACCURATE reading, I wouldn’t bother with the factory dash.

November 13, 2015 at 12:13 pm #11240When I had the sender in bottom hose if I was on fwy it would sit on 150/160F. Because the coolant in the radiator was so cool. Then out of no where the t/stat would open and the gauge would bounce straight to 210.

only way I believe the bottom hose would come close to being accurate would be if there was no t/stat.

November 13, 2015 at 11:10 am #11236Send a photo of what the problem is.

The sensor in the head reads a lot more accurate. I used to have mine in the bottom gauge and IMO is wasn’t as accurate as I would like it too be.

November 13, 2015 at 9:25 am #11222I had the factory one in the front of passenger side and my autometer on the rear.

November 13, 2015 at 8:45 am #11217The one being sold was the wrong size. It was too big and won’t sit on the knob properly. It was the size required to stamp the horn pad. I feel a bit sad for the person that paid $700 for it as it won’t work. In addition the gear knobs do not have the pronounced circle around the symbol like that stamp has. Again shows its for the steering wheel.

that was on FB other day?

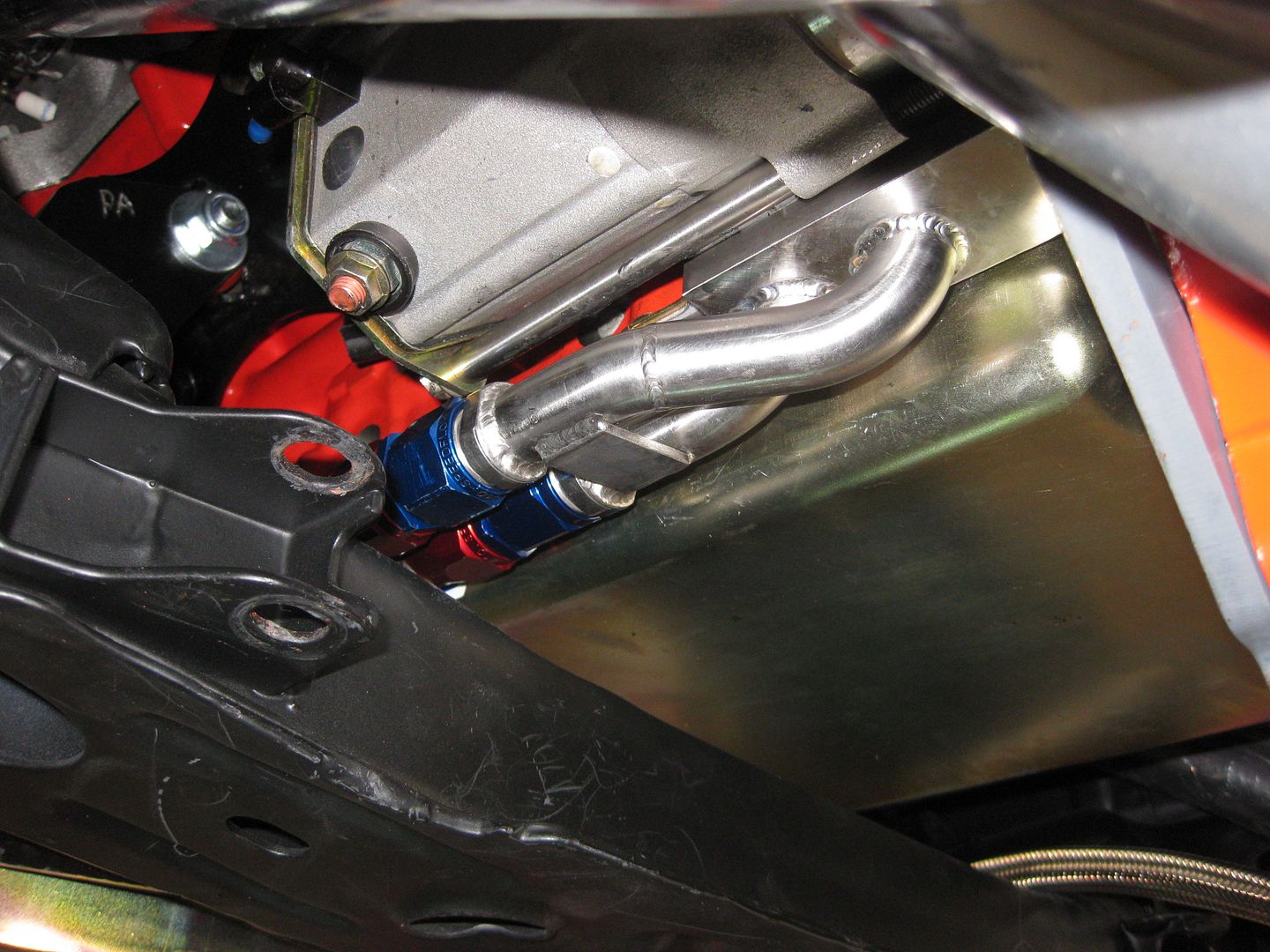

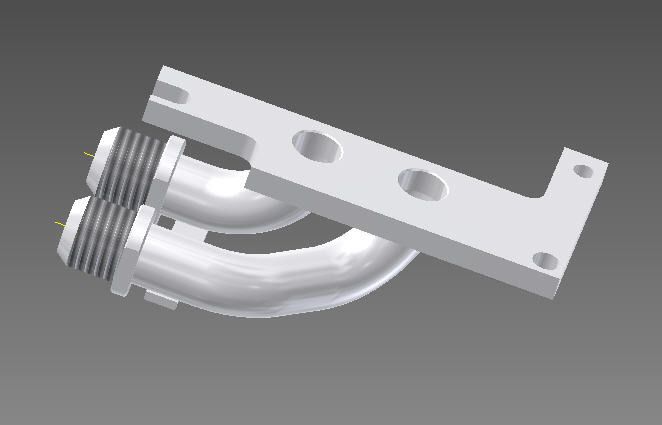

November 11, 2015 at 10:56 am #11125I used a Canton circuit racing sump (part number 15-276) https://www.cantonracingproducts.com/product/15-276/15-276—GM-LS1LS6-5-58quot-DEEP-FRONT-SUMP-DRIFTROAD-RACE–PAN/, its a beautiful piece of kit BUT…… I originally bought it thinking/hoping it would mean I wouldn’t need to modify the front K member. That proved out to be wrong and I still needed too. Also the design of it is you need to run an external oil filter (no biggie in fact I wanted that) but again, it just so happens this comes out pretty much directly over the steering rack. I had to design up a very nice stainless adapter to run the braided lines forward. Its very very neat, but took bloody ages to come up with how to do it and I am really happy with it but seriously its money you don’t need to spend. I do have a drawing of the adapter if you (or anyone else) goes that way I am happy to share if you wanted to get one made. So tbh if I were to do it again, I think the easiest/cheapest/neatest solution would be to use a VY sump (best internal baffles apparently) and simply trim back the two back corners and tig weld plates into the corners. That way it will clear the K member and you lose just a few ml of oil capacity which is insignificant. Now having said that, mines beautiful, large capacity, very very well baffled, magnetic drain plug, provision on the other side for a temp sensor or whatever. So if probably comes down to what your after.

Beautiful Gary. Looks like a VERY well built sump from the link. I remember you had to stuff around with the oil feeds. I was looking at a ls1 sump and then thinking of using an Improved Racing Baffle kit + crank scraper. ASR also make a modified windage tray which also looks like a nice piece of gear.

Just tossing up which was is best value for $$$

November 10, 2015 at 10:26 pm #11102Gary. What sump are you using?

I need to to buy one for mine

November 10, 2015 at 10:46 am #11087Hey mate. Were you thinking of going turbo? My turbo kit will be up forsale soon. Every piece of it. Even boost controller and full exhaust.

what ball park are u thinking. A mate of mine has hinted his looking.

November 10, 2015 at 10:22 am #11084likeing the looks of this with the ncop side of it the weight to power ratio is more of a guideline than actual written in stone rules as the engineer has to work to adrs as well he can take into account brakes chasis modifications etc to make up for the lower weight but alas it is up to if the engineer is confortable signing it off because if the shit hits the fan it may bite him in the arse. the engineer who signed off my car had the opposite drama with a patrol with an lsa because he was concerned the car was to heavy for that size engine (patrol was previously engineered for a duramax) haha on a side note cav have you still got the original ss seats from this and do you want to sell them at all

Exactly right mate. An LSA in a patrol would be awesome out in the bush.

Dont have the seat. Swapped them into my SS so I could sell that conplete

November 9, 2015 at 6:08 pm #11078nobody likes manuals anymore? :( sounds like changing gear yourself will be a lost art pretty soon…. I would have jumped at the Malwood T56 option! You get all the fun, highways would be a breeze, so what if you sacrifice a couple of tenths at the strip, it’s still going to be a friggin quick car?? doing a trackday or going for a drive down a windy mountain road would be boring as crap in an auto :(

nothing like click top gear whilst turning the tires off the clock without having to lift.

Just foot to the floor and row thru the gears.

Will be be heaps quick and MUCH nicer to drive.

November 8, 2015 at 2:46 pm #11032And I’m happy to hear it, but what IS the way around it? I really want to know. Everybody keeps telling me there is a way around it, but whenever I’ve asked an engineer I get the same story, refer to the table. BTW, vehicle manufacturers don’t have to comply with a COP for “modified vehicles” as their vehicles aren’t modified, but they are subject to destructive testing which wouldn’t be too popular with most resto guys!

How does Harrop offer factory warrenty then when they do blower kits?

November 8, 2015 at 1:12 pm #11027That’s it.

Just waiting on parts now really. Been pretty busy at home of late.

November 7, 2015 at 4:18 pm #11007There are a few loop hole. Some engineers are comfortable using them others are not.

Engineer is is currently doing an LSA into a VN which is at his shop. So I’ll basically copy what he does. But do it all my self so I’m saving $$$

Hoping to have conversion and glide in my possession by end of next week. Engine hopefully not long after.

-

AuthorPosts