Home›Forums›Technical – General›Driveline›VR/S Rear Sub Frame Stengthening

This topic contains 14 replies, has 5 voices, and was last updated by ![]() VRSenator065 9 years, 8 months ago.

VRSenator065 9 years, 8 months ago.

-

AuthorPosts

-

March 8, 2015 at 3:55 pm #2228

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

General

The rear sub frame on a VR and VS is a well known weak spot. They are very prone to cracking even with a standard 5L. So with mine I modified and strengthened it. There are a lot of different ways to do it, but very happy with how mine turned out, so thought I would post what I did.

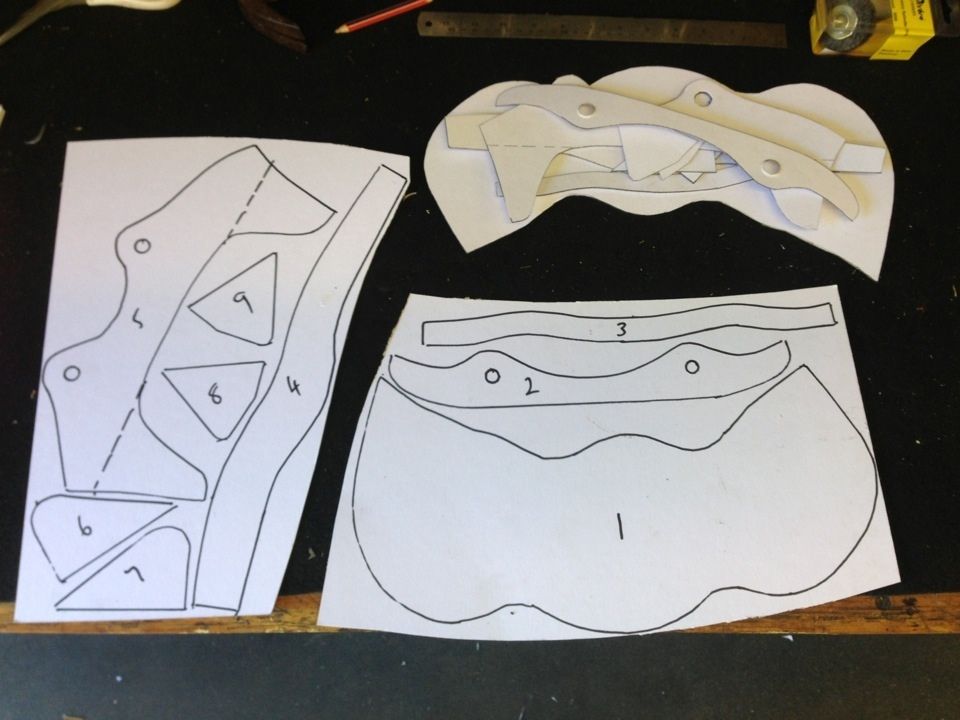

I made up cardboard templates, then took it to a welder that used the templates to cut the strengthening pates. He fully welded it all, then I had it powder coated back.I used 6mm plate for the top of the frame where the diff mounts, and also cut in a 10mm vertical member to tie the top and bottom together. I also added doubler plates to where the suspension arms mount as they tend to flog out when pushed hard. I also triangulated it all with gussets where ever possible.

This is how it turned out back from the powder coaters

And this is it all assembled.

March 8, 2015 at 8:14 pm #2253

March 8, 2015 at 8:14 pm #2253

KenthorParticipant- Canberra

- VS Acclaim - LS1 and HSV enhanced VS SS

View build HERE

Posts: 3I took a different approach, when I strengthened mine we added a 40mm flat bar around the edge as a border. Figured the the issue with them cracking is when the frame flexes so made sure it couldn’t flex.

Hoping these pics work!

Attachments:

You must be logged in to view attached files.March 8, 2015 at 8:22 pm #2260

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Cool, nice to see a different approach.

March 8, 2015 at 9:09 pm #2268

Brockfan05Participant- Albury

- VR Berlina 5.0L VS Clubsport

View build HERE

Posts: 39

This is actually one of the areas I was curious about strengthening on both my vr and vs. Fortunately both of my irs cradles are in good shape still. Thanks for posting this up guys, very helpful. Just out of interest Gary, did you have a slot cut into the frame top and bottom for the ten mm plate that was welded in? I’m just trying to work out exactly what you’ve done there is all.

-

This reply was modified 9 years, 9 months ago by

Brockfan05.

Brockfan05.

March 8, 2015 at 9:50 pm #2272

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Yea mate, I cut a lot top and bottom, dummied it up with a piece of 10mm thick timber, then replicated it in steel. The idea is is takes the torque as it loads up, works great.

-

This reply was modified 9 years, 9 months ago by

VRSenator065.

VRSenator065.

March 8, 2015 at 10:23 pm #2278

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

-

This reply was modified 9 years, 9 months ago by

VRSenator065.

VRSenator065.

March 8, 2015 at 10:46 pm #2282Why didn’t they make them like that out of the factory ;) hahaha

March 8, 2015 at 11:16 pm #2286

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

They probably didn’t expect us to be putting 1000rwNm through them

March 9, 2015 at 6:00 pm #2344

March 9, 2015 at 6:00 pm #2344

Brockfan05Participant- Albury

- VR Berlina 5.0L VS Clubsport

View build HERE

Posts: 39

Cool, thanks Gary. Did you use a plasma cutter to get the slot that accurate? It’s so neat lol.

March 9, 2015 at 7:08 pm #2347

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Nah mate, just very careful with a 4″ angle grinder and a 1mm cut off disc.

March 9, 2015 at 8:56 pm #2349They probably didn’t expect us to be putting 1000rwNm through them

Hahaha probably not hey :P

April 10, 2015 at 11:18 am #4426I put a 10mm plate across the top of the sub frame (like what you have done) and doublers on the trailing arm mounting bolts. Will be interested to see it’s condition after a few years on SSSL’s and a spool.

April 10, 2015 at 11:22 am #4429

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

I can’t remember who on SC suggested the doubler plates on the trailing arm bolts, I wasn’t going to do it, but apparently they flog out. I probably went a little overboard (surprise surprise) but at least its done. What sort of power are you putting through yours?

-

This reply was modified 9 years, 8 months ago by

VRSenator065.

VRSenator065.

April 13, 2015 at 1:57 pm #4622Nowhere near as much as you are, it’s the spool that was elongating them over time.

April 13, 2015 at 2:44 pm #4630

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Yea right, I have a locker, not as savage as a spool but I imagine still putting it under a bit more load than a regular lsd.

-

AuthorPosts

You must be logged in to reply to this topic.