Home›Forums›Members’ Builds and Rides›VN – VP – VR – VS›VR Senator with LSx454

This topic has been reported for inappropriate content

This topic contains 2,102 replies, has 82 voices, and was last updated by ![]() VRSenator065 3 years, 5 months ago.

VRSenator065 3 years, 5 months ago.

-

AuthorPosts

-

May 30, 2017 at 10:51 am #22975

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

What Crankcase breather set up do you run Gary?

Sorry mate I accidentally reported you!!

Good question, its always been an issue for me as (stupidly & stubbornly) shooting for the 100% street legal and fully engineered dream has caused issues particularly with my induction set up which pretty much creates zero vacuum. My engine from day one has always breathed at high rpm, many guys (including from the US have said that just how the LSx454 is. In case you ask compression is awesome and even, so there are no issues there that I know of.

I started off with the valley breather and valve cover breathers running to a non vented catch can, then to the vacuum manifold block which is plumbed to each of the eight runners. This was fine at light to medium throttle but would push the dip stick at 7k rpm, when i first had it tuned by Willall they said for them its a common problem, and they cable tied it shut when doing a power run.

I have since gone to the valley and valve covers going to an elite engineering catch can that is plumbed to the vacuum manifold via a non return valve. Teed into that line it runs to a standard style vented catch can under the inner guard again via a nrv. The idea is the vacuum handles it to a point but when it cant cope it vents to the under guard can which is vented. Purpose of the nrv’s is so it doesn’t suck air into the inlets messing up the map sensor.

All lines at present are about 3/8″, which i don’t think is enough.

Thoughts?

May 30, 2017 at 11:03 am #22977I Was always under the assumption that the valley should run to a seperate oil/air seperate and back into the system then have the valve covers government a seperate system. One has to breath out will the other sucks fresh air in?

no doubt Ian will know this a lot better then me. I was gunna make a catch can with a hidden filter going to atmosphere and then a fake like running back to the intake which was actaully internally blocked off.

May 30, 2017 at 11:13 am #22978

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Yea dunno, one thing I don’t like is the valley and valve cover tubes would be lucky to to be 10mm, maybe smaller. I am wondering if I need to get say -10 or -12 bungs welded to the fronts of the valve covers and take them to a vented can (or two). Maybe even take the valley cover off and do the same.

May 30, 2017 at 11:16 am #22979

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777 May 30, 2017 at 11:37 am #22980

May 30, 2017 at 11:37 am #22980

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Very interested in your input Ian? I think I remember you saying you have had issues with rear seal on some of your race engines?

May 30, 2017 at 11:42 am #22981I’ll be going -12 off the valve covers also. I’ll be getting some billet ones.

U can get billet valley covers. If it fits and works you could Weld a -12 bung to it also.

May 30, 2017 at 12:47 pm #22982

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

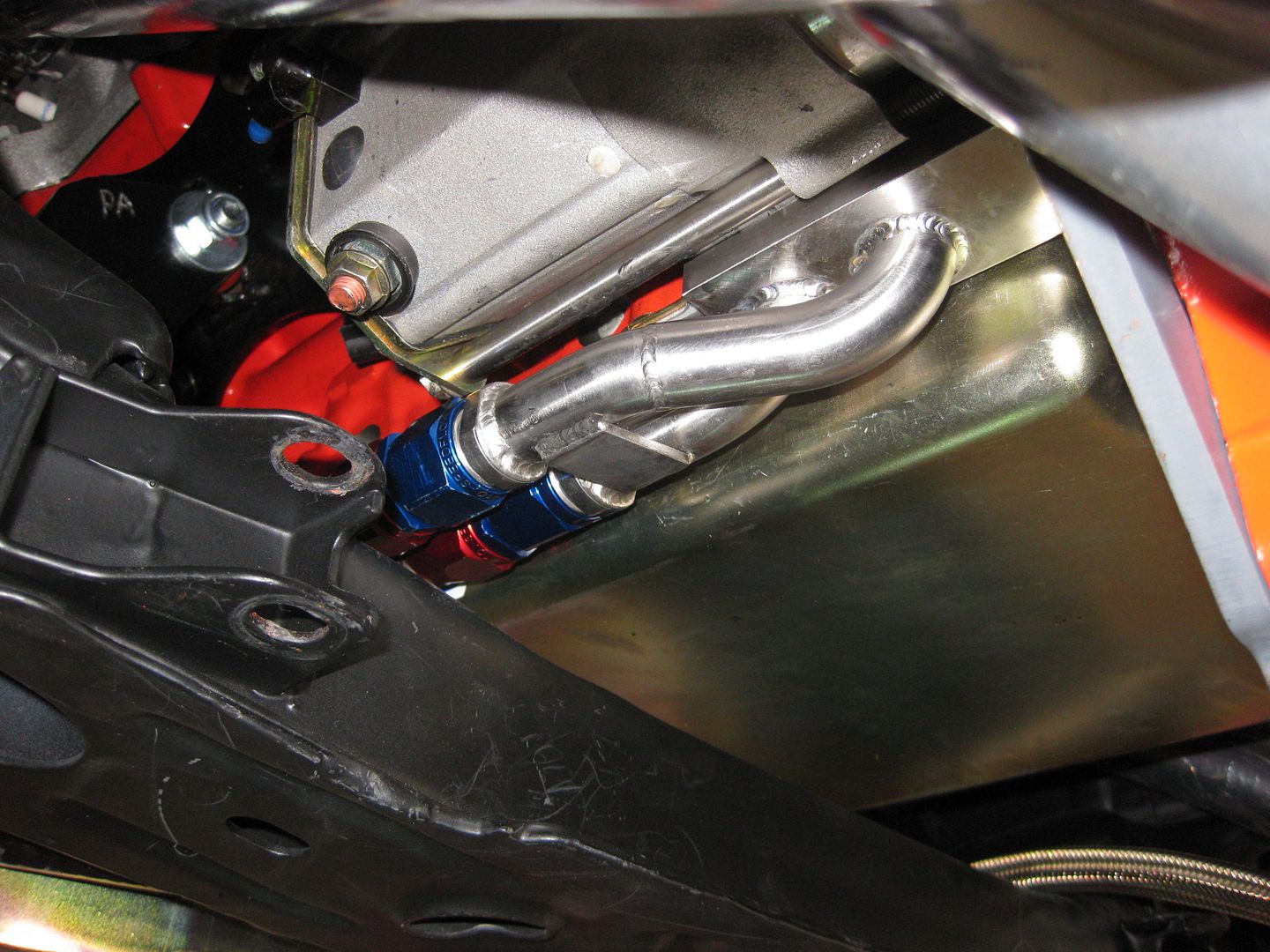

Well that’s a relief, just been around there, false alarm. Looks like the custom Gary Mc hybrid semi vented breather system works, its just a small leak from the gasket on the custom oil fitting for the remote oil filter and cooler. The rear main seal area is dry as a Nuns sense of humor. I think I will though at some stage get bungs welded to the valve covers but plumbing it the same was so it draws it into the manifold for light load. Cav mine have the LSx454 logo etc on them so I would rather mod them, but it would mean getting them re powder coated after. Also be careful as you are going engineered aren’t you? It cant vent to atmosphere (technically)

Its weeping around here;

May 30, 2017 at 2:54 pm #22985I had Dramas with my Blower engine, first rev to 6K in the Shed Hosed a couple of litres out the rear main seal…

In a Panic I pulled the engine and changed the seal before I realised it’s NOT a Lip type seal so it will recover without needing replacement… DOH

I ended up with a -10 from the Pass Valve cover to the Catch Can, from there it goes to a Non return valve and then into the Airbox Lid, in between there’s a T with a -6 Line to a PCV and that goes into the Blower intake, the “theory” behind this is if it ever exceeds what the -6 line can flow the non return opens and vents the excess into the AirBox lid.

In practice it works perfectly never had an issue since it’s been plumbed this way, I also run a -6 return from the bottom of the catch can back into the Sump as my catch can does a really good job of separating the Oil from the vapours.

May 30, 2017 at 3:13 pm #22986

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Thanks very much Ian, your sysytem sounds perfect, a better version of what I have but I really like the idea of also incorporating the different size hoses as a way to almost direct the operation and then into the air box or blower. An issue with mine with trumpets is that part hasn’t been so easy, which is why its vented but once I get this cai air box idea finished that probably gives me somewhere to plumb that too. Excellent thanks.

May 30, 2017 at 9:32 pm #22994ITB’s are always a bit more complex, agree once the Airbox is done you’d be able to run a system much like mine to good effect, it’s just a fact of life these engine breathe a little heavy under power and the stock system just won’t flow the volume required so they push the dipstick and can weep at the rear main..

I even went to the effort of turning up an alignment tool for the rear seal housing..

May 31, 2017 at 6:35 am #22995

May 31, 2017 at 6:35 am #22995ITB’s are always a bit more complex, agree once the Airbox is done you’d be able to run a system much like mine to good effect, it’s just a fact of life these engine breathe a little heavy under power and the stock system just won’t flow the volume required so they push the dipstick and can weep at the rear main.. I even went to the effort of turning up an alignment tool for the rear seal housing..

Apparently there is a proper tool so you can aline the rear main properly. I winged it and the bloody thing wept.

May 31, 2017 at 9:03 am #22996I have a machine shop at home so made my own..

There’s also a proper tool to do Reluctor changes, I winged that one and got it perfect.

May 31, 2017 at 9:11 am #22997

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

^agree I’m not “Mr Engine”, but the years playing around I have never seen anything making decent power that doesn’t suffer some blow by at high rpm, its just a fact of life. If/When I build this I think a vacuum pump set up with the right rings to suit is a nice way to make some extra power and also solve the issue, but that’s a long way off.

The pic above at first glance look like you are setting up for a torque tube to run a transaxle….

-

This reply was modified 7 years, 5 months ago by

VRSenator065. Reason: bloody auto correct!!

VRSenator065. Reason: bloody auto correct!!

May 31, 2017 at 12:43 pm #22999I have a machine shop at home so made my own..

There’s also a proper tool to do Reluctor changes, I winged that one and got it perfect.

There’s also a proper tool to do Reluctor changes, I winged that one and got it perfect. we aren’t all that fortunate 😩

Yeah I only recently seen the reluctor tool also.

May 31, 2017 at 1:12 pm #23002mmm transaxle…

I was lucky I had my old stock crank here so was able to get very accurate dimensions from it before I started!

Didn’t even need a Crank Relearn!

June 8, 2017 at 1:36 pm #23048

June 8, 2017 at 1:36 pm #23048

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Well not totally happy that my “best i could buy” SPAL3000 fan has decided to die. I bought it 3 years ago but its seriously done stuff all miles. Anyhow bought another, its fitted, also I think fixed the small oil leak, so its back on the dyno. Lets see how it goes now…

June 8, 2017 at 5:47 pm #23049Back on the dyno? Did do tweaks? Or just finalising the tune?

Hows the intake tracking?

June 9, 2017 at 9:37 am #23060

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Nah mate just finishing the tune, seems the lift pump has been an issue for a while, and so there’s more to the tune than a simple quick minor tweak. It’s getting a bit frustrating how longs it taking to be honest. Dealing with tuners has to be the worst part of this whole bloody build. If I was a bit younger and had more time on my hands I would learn it myself but just too much other stuff happening in my life to start down that path.

The CAI is parked as I have an issue with the print head on the 3D printer which has had to be sent back to the factory for. All the parts are modeled up so once the printer is back in action its full steam ahead.

My brother is back in Australia for the first time in a few years, he has never heard the car run let alone go for a drive. I am bloody itching to get the tune done so i can take him for a spin, then I will swap back to the dummy bonnet and finish off the CAI.

Then I think its a run at the 1/4 to see where it stands as is. My guess is mid 11’s, not sure. Then at least I will know what I need to do to grab that 10 I want.

June 16, 2017 at 11:51 am #23195

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Very nice when you drop in unexpected at the tuners and he runs across the workshop at you smiling saying I can’t wait to show you this. Its secret mens business that he has asked me not to say in any detail but there is something within the tune that Willalls, also Webber missed that he has played with that has just made the throttle response almost more crazy instant. He got me to start it and spin it up a bit on the dyno and fark me, as if it needed more low down torque but man, its crazy. Of course it means he wants it longer as it effects everything. He says there are some quite significant differences due to the ITB’s. Apparently the secret to it, if there is one, is he is tuning it with the full gas analyzer up its bum. Stephen is all about getting the perfect burn, according to him, perfect burn = max torque = max power. Not sure it will make any more power at wot, but for me the cars never been about that (yet) its about throttle response and low down torque. Fingers crossed I get it back end of next week. Then I reckon its time to find a nice private road, someone with a camera phone and fry some rears.

June 17, 2017 at 11:39 am #23210What size converter do you run?

-

AuthorPosts

You must be logged in to reply to this topic.