Home›Forums›Members’ Builds and Rides›VN – VP – VR – VS›VR Senator with LSx454

This topic has been reported for inappropriate content

This topic contains 2,102 replies, has 82 voices, and was last updated by ![]() VRSenator065 3 years, 5 months ago.

VRSenator065 3 years, 5 months ago.

-

AuthorPosts

-

March 15, 2017 at 4:18 pm #22048

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Pretty sure I am right but won’t lie you have me thinking. So to be sure have just written a detailed email with a heap of screen shots off the CAD and pics to Mike Jenvey in the UK, who has become quite interested in what I am up to with the car. In the past he has been super helpful, so be interesting to see what he has to say. Won’t hurt to listen to the expert and incorporate what he suggests. Will post back when I get a reply.

March 15, 2017 at 6:07 pm #22050Dyno won’t show the gain. Track will.

March 15, 2017 at 7:07 pm #22051Sorry cava, but I’m pretty sure the dyno will tell you straight away if there’s any improvements or most importantly if there’s any restrictions or problems, because you can just pop the bonnet to see the difference between the cold air set up and open airboxes.

Surely it would have to make an improvement though especially if the airboxes you’ve made are bigger than what came with the manifold and the ducting feeding it should be big enough. Only one way to find out

March 15, 2017 at 8:15 pm #22052Not when there is a dirty big fan blowing towards the engine bay.

True indication will be at the track. Making extra hp on the dyno doesn’t always make it faster.

-

This reply was modified 7 years, 7 months ago by

cava454.

cava454.

March 15, 2017 at 9:31 pm #22054How would it “starve” the rear cylinders?

March 16, 2017 at 5:43 am #22055Yeah even so cava the dyno will pick up any improvements or problems, we have a similar situation with the airboxes we use at work, they’re not as restrictive as some airboxes but even though we use the biggest filter we can and the airboxes have a 4″ inlet and outlet the cars we use them in perform better with the airbox lid removed to get more air into the engine, we put 6.6 duramax engines into just about anything but mainly 4x4s

March 16, 2017 at 9:57 am #22056

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Thinking more about this overnight, as Ian says gotta say I cant see what the issue will be. I mean Harrop doesn’t seem to have an issue with it, and Jenvey also do a similar thing themselves as I posted above. Also think there’s sometimes too much discussion with this car about ultimate track performance and dyno numbers. It’s a street car, it makes enough power and torque now to blow a set of tyres off idle. Its making 800+Nm of tractive effort at 2,000rpm and its bone crate stock and passes an IM240 emissions test. Surely the gain in getting nice fresh cool air to the engine will way outweigh any unevenness in cylinder feed. Imagine the poor rear cylinder now.

March 16, 2017 at 9:59 am #22057

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777 March 16, 2017 at 10:49 am #22058

March 16, 2017 at 10:49 am #22058Cheeky buggers ay lol, yeah I agree cold air has to be an improvement over hot engine bay air

March 16, 2017 at 11:10 am #22059Bit of a Hint is engines don’t open all the intake valves at the same time…

March 16, 2017 at 11:16 am #22060

March 16, 2017 at 11:16 am #22060

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Bit of a Hint is engines don’t open all the intake valves at the same time…

Yea good point I remember my Dad teaching me this back in the day when I had a set of triples Strombergs off an XU1 on my Torana. I said I was surprised that the size of each of the triples was similar to the original single barrel carby. He said as you say that even though I had gone from 1 to 3 carbies, the engine only “saw” it as one carby, as it was drawing one carby per intake cycle if that makes sense.

March 16, 2017 at 11:37 am #22061We’re comparing pre ITB to runner distribution. Completely different kettle of fish.

March 18, 2017 at 1:13 am #22066I’m with cava, don’t think you will see any difference on dyno

maybe with bonnet down before and after you might but not with the bonnet open before and bonnet closed after

the track is the spot to tell how good this will work

either way I think your on the right track Gary and won’t have any problems, N/A cars suck all there air through a 90mm or smaller throttle body so I don’t see how 2 by 250mm by 150mm Intakes to 2 by air box/planiums alomost that probley hold 3-5L each would be any problem

March 18, 2017 at 3:37 pm #22070Agree on dyno cant see it making a big change maybe a little.

However on street or track will be notable change with cooler air pushed/sucked in…imagine difference be like driving on hot day then again on cold night.

March 18, 2017 at 3:50 pm #22072

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

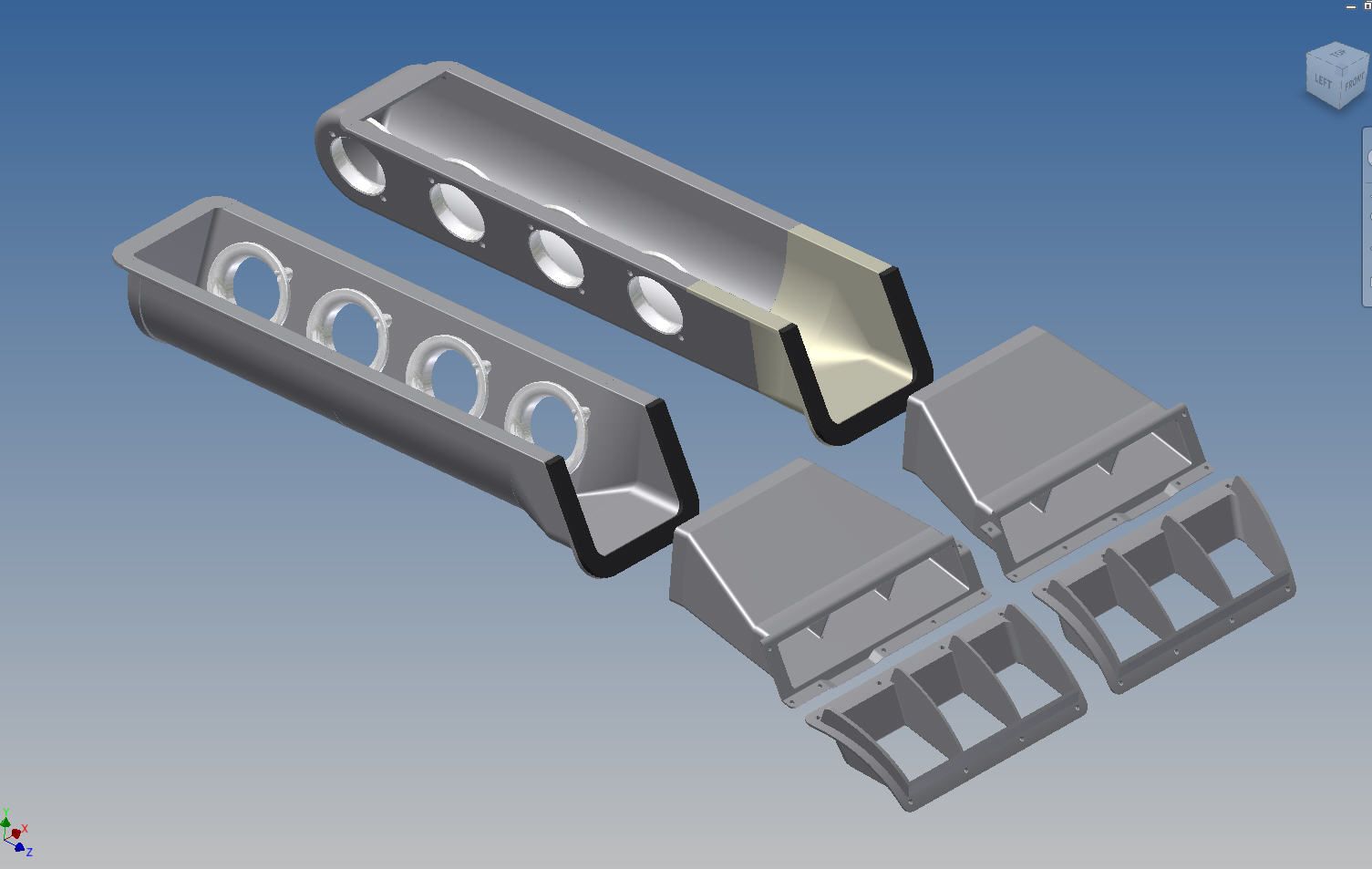

Cheers all, pretty much agree. So feel like I have pretty much broken the back of the work design/layout wise, so I am confident I can make it all work. The part that attaches to the rear of the front bonnet rib, I have called the Rear Bulkhead piece, I have got to fit to the rib very nicely given there’s a fair bit of contours to it. My printer will go to a max size of 275mm so eventually I will break it into those size chunks. For prototyping I do smaller sections, perfect that fit then move on. I have come up with a nicer shaped entry vent rather than a plain rectangle. I really think its all going to work pretty well. I have delved in my fading old memory CAD modelling wise, theres quite a few tricky parts to it all, like the transition at the front of the plenums going from rectangular angled to the asymmetric shape of the actual plenum. I have also so got on order some black fanged screws so it looks more factory than the stainless screws. Parts take hours to print, so its a case of trial and error with a long delay in between. Have just run out of ABS so may not get to do any more printing this week end but may start on the final transition piece that mates with the front of the plenums when the bonnet comes down. Then its not too far from modifying my actual bonnet.

-

This reply was modified 7 years, 7 months ago by

VRSenator065.

VRSenator065.

March 18, 2017 at 5:30 pm #22074That’s the shit right there GARY 👌👌👌👌👌

i might even even be interested in one.

How do you going the seperate pieces together?

March 18, 2017 at 6:09 pm #22075Where do the filters end up?

March 18, 2017 at 6:23 pm #22076

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

IJ not sure my original idea of filters are going to work, do have another plan, but worse case at least its got cool air going to it. Cav a mixture of bonded, but the intake ones in the bonnet will be a slip on fit.

March 18, 2017 at 6:40 pm #22077Try integrate a panel filter in there some how like and OTR. You would be amazed at how much crap an OTR filter picks up.

Your situation would be no different.

March 18, 2017 at 8:25 pm #22078Luckily it’s an iron thickwall block so you’ll get a few bores out of it… personally I wouldn’t run without a filter full stop but that’s just me..

I’m with Cav on this one I’d use a couple of panels if at all possible.

Looking at the pics with a bit of a redesign you could have them in the Nostrils.

-

AuthorPosts

You must be logged in to reply to this topic.