Home›Forums›Members’ Builds and Rides›Non-Commodore Rides›The 'LOLVO'

This topic contains 53 replies, has 12 voices, and was last updated by ![]() VRSenator065 7 years, 10 months ago.

VRSenator065 7 years, 10 months ago.

-

AuthorPosts

-

May 10, 2015 at 9:44 am #6592

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Why have you gone back to original manifold or are the pics mixed up ?

Got an LS6 intake for nothing and would have had to buy a 4 bolt throttle and fuel rails to suit the Edelbrock one. Decided against it to keep costs down.

May 10, 2015 at 10:09 am #6594

KAL SPLParticipant- Orange NSW

- L67 VS Calais FSM Niki VS GTS/R replica

View build HERE

Posts: 64Isn’t ls6 a bolt bolt TB ? Put that on the edelbrock ? I would have thought edelbrock be better for this application.

May 10, 2015 at 10:11 am #6595

KAL SPLParticipant- Orange NSW

- L67 VS Calais FSM Niki VS GTS/R replica

View build HERE

Posts: 64My bad just checked pics still 3 bolt , I picked up an ls2 manifold cheap for mine and they’re 4 bolt and can accept much bigger TB but I guess that’s not crucial in turbo application hey ?

May 10, 2015 at 2:09 pm #6606

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Exactly. Really doesn’t matter with turbo, which is kinda the reason I put 241 (LS1) heads on this 6L block. Fits, cheap, works.

May 10, 2015 at 2:51 pm #6607Throttle body size actually does matter, it actually matters a lot

This is something iv found on a another forum when looking at weather my 2.75 inch pipe would do for my v7 blower and the answer was no it wasn’t big enough

>0.4 Mach is the point at which air becomes turbulent and losses in efficiency start to occur exponentially. The key is to stay under that speed. You want to use the smallest piping possible that still flows enough to meet your needs. Larger than necessary piping increases lag time with no measurable gain

The velocities are in miles per hour and mach, and the flow rates are in cfm. Measurements for the piping are in inches.

2″ piping

1.57 x 2 = 3.14 sq in

300 cfm = 156 mph = 0.20 mach

400 cfm = 208 mph = 0.27 mach

500 cfm = 261 mph = 0.34 mach

585 cfm max = 304 mph = 0.40 mach2.25″ piping

3.9740625 sq in = 1.98703125 x 2

300 cfm = 123 mph = 0.16 mach

400 cfm = 164 mph = 0.21 mach

500 cfm = 205 mph = 0.26 mach

600 cfm = 247 mph = 0.32 mach

700 cfm = 288 mph = 0.37 mach

740 cfm max = 304 mph = 0.40 mach2.5″ piping

4.90625 sq in = 2.453125 x 2

300 cfm = 100 mph = 0.13 mach

400 cfm = 133 mph = 0.17 mach

500 cfm = 166 mph = 0.21 mach

600 cfm = 200 mph = 0.26 mach

700 cfm = 233 mph = 0.30 mach

800 cfm = 266 mph = 0.34 mach

900 cfm = 300 mph = 0.39 mach

913 cfm max = 304 mph = 0.40 mach2.75″ piping

5.9365625 sq in = 2.96828125 x 2

300 cfm = 82 mph = 0.10 mach

400 cfm = 110 mph = 0.14 mach

500 cfm = 137 mph = 0.17 mach

600 cfm = 165 mph = 0.21 mach

700 cfm = 192 mph = 0.25 mach

800 cfm = 220 mph = 0.28 mach

900 cfm = 248 mph = 0.32 mach

1000 cfm = 275 mph = 0.36 mach

1100 cfm max = 303 mph = 0.40 mach3.0″ piping

7.065 sq in = 3.5325 x 2

300 cfm = 69 mph = 0.09 mach

400 cfm = 92 mph = 0.12 mach

500 cfm = 115 mph = 0.15 mach

600 cfm = 138 mph = 0.18 mach

700 cfm = 162 mph = 0.21 mach

800 cfm = 185 mph = 0.24 mach

900 cfm = 208 mph = 0.27 mach

1000 cfm = 231 mph = 0.30 mach

1100 cfm = 254 cfm = 0.33 mach

1200 cfm = 277 mph = 0.36 mach

1300 cfm max= 301 mph = 0.39 machMy v7 blower at 100% runs 1400cfm but I don’t have it at 100% so 3 inch was perfect for me and my pipe at full boost would be bust on the limit of nearly 300mph air speed

In order to convert from Lb/Min to CFM for the equation above, you take the flow rate in Lb/Min for your turbo (generally an educated guess based on the pressure ratio and power created) and multiply it by 14.27. That will yield the CFM flow for your setup.

For Example:

T3/T04e 57trim .63ar @ 21psi makes 452 whp

This turbo is known to have a 50lb/min compressor wheel which will make ~500bhp. Since we’re using whp above, we can assume this turbo is pretty close to its max of 50lb/min.Now to convert that to CFM, you take 50lb/min x 14.27 = 713.5 CFM. When you refer to the table above, you can see that we’re starting to max 2.25″ piping, but we’re still in the “good” range for 2.5″

but it also depends on how smooth the piping is inside… and all the bends. this i would say is ” perfect piping conditions” and if you would pick a number to upsize your piping at it would be when you hit about the .3 maximum .35 mach region.

-

This reply was modified 9 years, 7 months ago by

vs manta 218.

vs manta 218.

May 10, 2015 at 2:58 pm #6610And throttle body falls under the same size system

I dont know what size a factory 3 bolt LS throttle body is though

May 10, 2015 at 3:00 pm #6612

ajvx01Participant- adelaide

- VC 308 taxi bt1 wanna be!

View build HERE

Posts: 102

that’s great info^^

May 10, 2015 at 7:07 pm #6622

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Ok maybe it matters, but in the grand scheme of things it doesn’t matter to me. Plenty of guys in the states pushing north of 1500hp with the stock 78mm throttle, will be plenty for me.

May 10, 2015 at 7:34 pm #6625Yes exactly, 78 mm is slightly bigger then 3 inch so is good for 1200hp or so perfectly sized

Before it could get more efficiency from goin larger but will still work with more hp like you say others have pushed 1500hp

personally i I would stay at 78 mm as well with mathematic side of things

epic build design

May 21, 2015 at 5:17 pm #7104

May 21, 2015 at 5:17 pm #7104

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Well, made some progress. Got all the bushes out after a lot of swearing, cutting and burning. Got the wire wheel out and cleaned up all the old paint, rust and sound deadening which Volvo spray all over absolutely everything. Gave the parts a fresh coat of rustproof paint, put some new bushes in and started putting some stuff back together.

I cheated a little putting the replacement bushes in but cutting them down the centre with a hacksaw and pressing them in from either side. I can’t see any reason this would cause any harm and saved a lot of dicking around.

May 21, 2015 at 8:09 pm #7112You can buy 2 piece bushes so couldn’t see what the different would be

July 7, 2015 at 2:06 pm #7918

July 7, 2015 at 2:06 pm #7918

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Update!

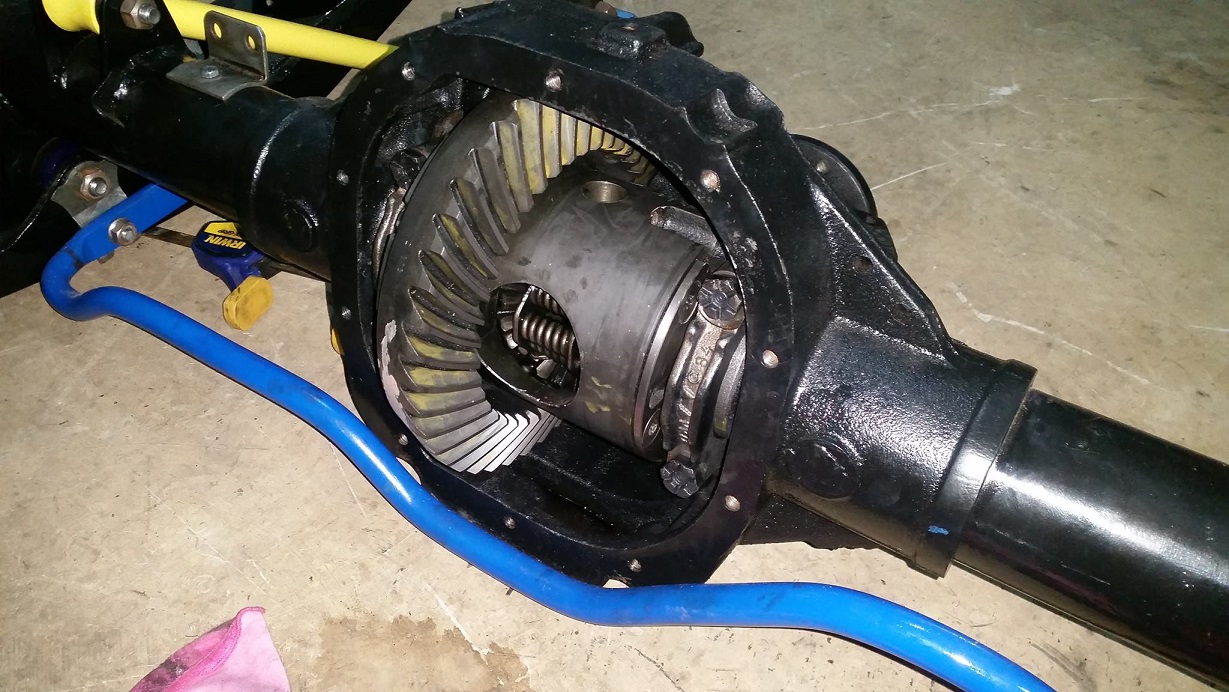

Last test-fit of the diff before modifying torque arms.

And assembled with new LSD.

This bearing caused a lot of trouble and needed to be removed by force.

Adjusters done.

Installed.

Will need to elongate the holes in the swaybar so it clears the diff cover. The panhard rod also hits the ring gear, so will need to do some modifications there…

Also picked up some Ford AU Fairmont wheels. They fit perfectly and don’t look too out of place on the Volvo.

Cold-side done.

Next up is the brake lines, the radiator fans, shroud and hoses, and then wiring.

Volvo has been pushed outside for the moment. My other car needs a bit of TLC.

December 10, 2015 at 4:58 pm #12083

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Hows this bad boy going?

December 11, 2015 at 12:37 pm #12088

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Hows this bad boy going?

Slowly. I haven’t touched it for months, been getting power and stuff sorted in the shed which is finally done as of today. I have a delivery of parts from Summit which need to go in the Lolvo, so hopefully I’ll get back into it next week :D

December 11, 2015 at 12:54 pm #12090

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Cool, update when you can, love this thing

December 31, 2015 at 1:53 pm #12867

December 31, 2015 at 1:53 pm #12867

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Long time between updates… I actually recorded a progress video in April but I think I forgot to link it up.

More progress has been made since then, I’ll do another video shortly!

December 31, 2015 at 2:10 pm #12868Nice Vid Nem, thanks for that!

December 31, 2015 at 2:27 pm #12869

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Nice vid, love the “exhaust”

December 31, 2015 at 2:40 pm #12870

December 31, 2015 at 2:40 pm #12870

SirNemesisParticipant- Geelong, VIC

- 2002 WHII Statesman 1985 Volvo 240GLE

View build HERE

Posts: 25Current progress video!

https://www.youtube.com/watch?v=gGyrNyh-rJ0

I feel as though I’ve recently spent too much money on things for this car that might actually not be cheap shit. This is concerning, perhaps I’m starting to appreciate this car too much…

-

This reply was modified 8 years, 12 months ago by

SirNemesis.

December 31, 2015 at 2:56 pm #12874Taking pride in what you’re doing is never a bad thing..

-

AuthorPosts

You must be logged in to reply to this topic.