Home›Forums›Technical – General›Suspension›Modified IRS K-frame for Lowered Cars

This topic contains 92 replies, has 14 voices, and was last updated by ![]() [TUFFVQ] 8 years, 5 months ago.

[TUFFVQ] 8 years, 5 months ago.

-

AuthorPosts

-

November 14, 2015 at 1:13 pm #11281

Apparently Star Performance use to modify the rear to correct the camber back in the day. I knew a guy with a VT that had it done.

November 14, 2015 at 5:48 pm #11286

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Yep as Jaba said, they are so you can run 345 wide tyres.

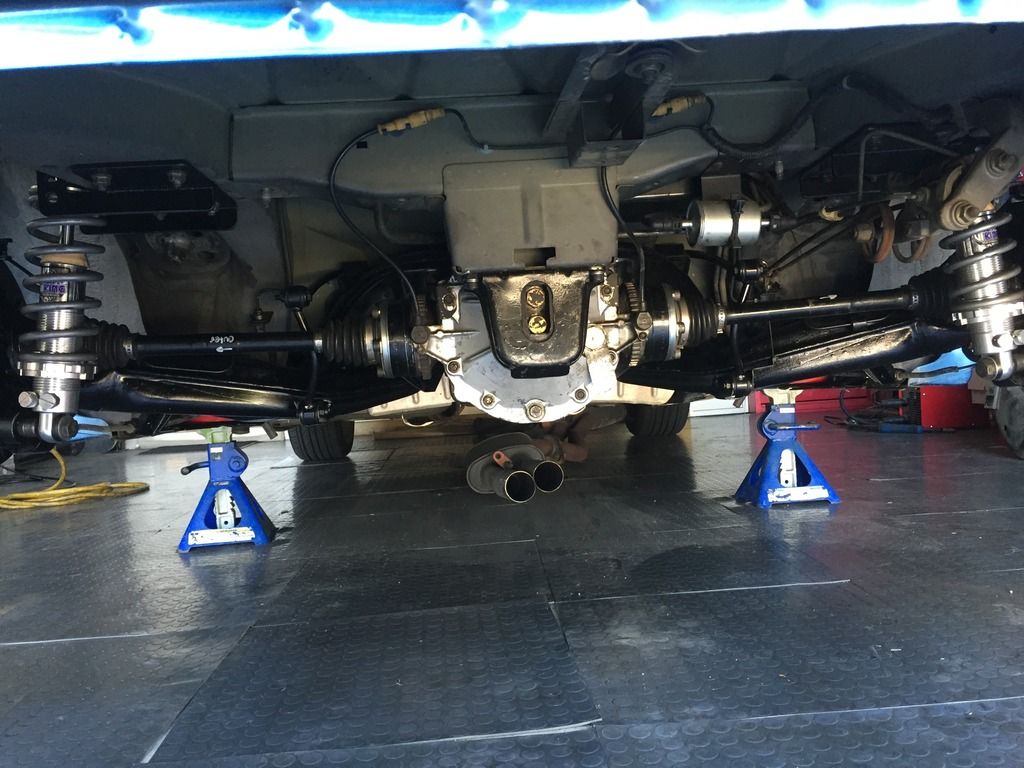

November 16, 2015 at 8:54 pm #11362Sorry for the delay, ive attached some pictures.

Lower mount for coilovers has been extended with 4340 chromoly, it has been welded to the original mount and tapped for longer m14 bolt. This is in a ute so the upper mount bolts in place of the factory shock mount.

The car feels heaps better than the original setup and the shock/spring is now behind the diff so helps with weight transfer.

November 17, 2015 at 7:43 pm #11390Looks good but it looks like you only linked thumbnails. Maybe someone more in tune with this forum can tell you how to link photos properly.

I assume thats installed in your VU?

November 17, 2015 at 8:19 pm #11396Looks good but it looks like you only linked thumbnails. Maybe someone more in tune with this forum can tell you how to link photos properly. I assume thats installed in your VU?

Yeah sorry posting off the phone so bit limited and rushed.

Yep this is in the VU, I’ve used a VY sedan subframe and control arms as you can get the shocks more upright with the extensions then the ute control arms, also you can use toe rods which I’ve made out of chromoly with rod ends.

November 17, 2015 at 9:12 pm #11398Do you know if the same thing can be done with the VP/S subframes

November 18, 2015 at 5:04 am #11401Do you know if the same thing can be done with the VP/S subframes

Can’t see why not, the subframe is similar, but the control arms are different.

Not sure how much clearance from the mount to the body the vp/s has though. You will need 50mm from the centre of the original mount hole to the body at the lowest point minimum.

November 18, 2015 at 11:25 am #11407

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Hey Brad, great mods, given the interest in this thread, if at some stage you can re-post those images full size would be great. This is the link to how to do it if your not sure. http://www.commodoresplus.com.au/forums/topic/posting-images-using-photobucket-attachments/

cheers

November 18, 2015 at 1:04 pm #11417November 18, 2015 at 1:30 pm #11421Far out someone knows how to weld there………..

November 18, 2015 at 2:50 pm #11429

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

You sir are a legend!!!

November 18, 2015 at 3:39 pm #11433Far out someone knows how to weld there………..

Thanks mate.

You sir are a legend!!!

No problems.

I have all the measurements and most stuff drawn on cad, so if anyone needs info just ask.

November 18, 2015 at 3:41 pm #11435

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

No problems. I have all the measurements and most stuff drawn on cad, so if anyone needs info just ask.

And that is exactly what I love about this forum, nice work.

November 18, 2015 at 4:10 pm #11436Curious what kind of welder/rods you used for that?

November 18, 2015 at 5:37 pm #11438Curious what kind of welder/rods you used for that?

I have a digital ac/dc tig, filler rods are Cigweld high test rt60 using 2.4mm 2% thoriated tungsten sharpened to a long pointed tip, I use a foot pedal so set max amps to 110.

November 18, 2015 at 5:40 pm #11439Curious what kind of welder/rods you used for that?

I have a digital ac/dc tig, filler rods are Cigweld high test rt60 using 2.4mm 2% thoriated tungsten sharpened to a long pointed tip, I use a foot pedal so set max amps to 110.

Awesome info thanks Brad, I’m a total Muppet on Steel so having a good starting point will help!

November 18, 2015 at 6:25 pm #11441Nice stuff there Brad, pitty you aren’t in VIC :P

-

This reply was modified 9 years, 1 month ago by

dazedv3.

dazedv3.

November 18, 2015 at 7:05 pm #11445

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Curious what kind of welder/rods you used for that?

I have a digital ac/dc tig, filler rods are Cigweld high test rt60 using 2.4mm 2% thoriated tungsten sharpened to a long pointed tip, I use a foot pedal so set max amps to 110.

Nice tig welding is like looking at mechanical porn…

November 18, 2015 at 8:02 pm #11449Thanks for the nice comments fellas.

November 24, 2015 at 6:35 pm #11645So these cradle extension boxes are they purely for running coilovers/tubed control arms or could u weld them in and have the rest stock just lowered to help with camber?

-

AuthorPosts

You must be logged in to reply to this topic.

[/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url]