Home›Forums›General›The Pool Room›Build Ninja – 3D Printing – *New Designs Available*

This topic contains 55 replies, has 17 voices, and was last updated by ![]() vspete 7 years ago.

vspete 7 years ago.

-

AuthorPosts

-

February 11, 2016 at 9:05 am #14003

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Hi all, well after following the development of desktop 3D printing over the last couple of years I have decided to go out and purchase one. I have bought a Lulzbot Taz 5, it a high quality machine with a large print volume, basically you could print something the size of a motorcycle helmet. It will print in all sorts of materials.

I have called myself Build Ninja, and my daughter has gone partners with em and developed the website etc. Link is here

https://www.buildninja.com.au/

Those of you that know me, would know that I am a 3D modeller, and have done some custom bits and pieces for forum members on here already. My daughter and I have gone halves in the printer, and we are going to start a small online business designing and making custom parts. My daughter actually created this forum, and she is going to be the guru in charge of the website creation with point of sale stuff etc, I will do the designing and manufacturing.

Its just a hobby really, but we are going to charge a small fee for the service but just to pay for materials etc. We will let you know when its up and running.

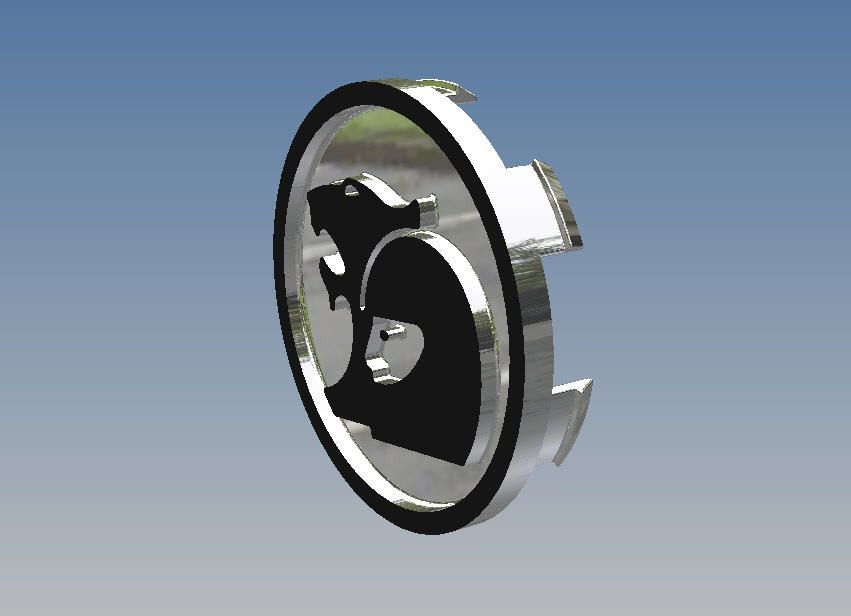

Some of the parts I have in mind are custom wheel centres, gauge clusters, custom badges etc. These are some of the things we have done or are planning. Btw, the wheel centre is one I did for Jake a while back, I wouldn’t use the HSV logo as its copyrighted, but more custom.

So if there’s anything you want, or think might be cool, let me know. Whilst i am learning I will probably do some freebies

-

This topic was modified 7 years, 1 month ago by

VRSenator065.

VRSenator065.

-

This topic was modified 7 years, 1 month ago by

Admin.

Admin.

-

This topic was modified 7 years, 1 month ago by

Admin.

Admin.

February 11, 2016 at 10:08 am #14010Just epic that is all…

Wish you all the successes with this venture.

With the centre caps how would you get a chrome/silver finish on them?

-

This reply was modified 8 years, 10 months ago by

sands vs.

sands vs.

February 11, 2016 at 5:50 pm #14020Wanna make me a dash to house my race pak.

February 11, 2016 at 6:04 pm #14023Need to get friendly with someone that does vacuum metallising so you can make em exactly like the LSXCEN rendering

February 11, 2016 at 6:26 pm #14024

February 11, 2016 at 6:26 pm #14024

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Pretty sure vacuum depositing works on dead flat surfaces out of an injection moulder. Plenty of contacts in the auto industry buddy, i grew up in Elizabeth where Holdens are/were made

Yes Cav, for sure, but not for nothing…

-

This reply was modified 8 years, 10 months ago by

VRSenator065.

VRSenator065.

February 11, 2016 at 6:41 pm #14028

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

So this is sort of an idea in my head. Lets say Cav wants a dash to suit his car, if I think its something others might want, I will do his for free, but then I want to be able to make more and sell them to other guys who might want them. But its just the start of an idea, not sure if or how it will work. Its just the modelling takes hours and hours, there is just no way to recoup that time in a single unit. For example my rear wheels probably chewed 80 hours in CAD time, so thats roughly $8k, who would drop that on a pair of wheels? But make a few, and it starts to make sense, same sort of deal.

What do you guys think of that idea?

February 11, 2016 at 6:50 pm #14029I personally think thats a great idea. Im sure there are plenty of custom pieces you could do that are going to apeal to more then just the person with the original request. Maybe worth posting up a general idea of the proposed product on here and the facebook page to gauge the interest and costings for original request/costings for those who may want that piece aswell. Im sure there is a more streamed lined way to get the numbers without wasting lots of time. This will definately take off and cover the costs if parts suit a few people each time

February 11, 2016 at 6:54 pm #14030Great concept but be careful these things can get away from you, I spent 12 years making parts that started as a hobby :XD:

February 11, 2016 at 8:58 pm #14038Nothing in life is free Gary. Was tongue in cheek lol.

The world is your oyster tho. Let me know when your making prototype turbos. I’ll jump on the free testing for that hahhaha

February 12, 2016 at 2:42 pm #14069

pir4teParticipant- Mallala

- 640 HP hyper-cruising SS-V Flagonwagon

View build HERE

Posts: 154

Wow that’s fantastic. So could you make a custom thermostat housing for example?

Naturally as-pirated, all-motor.

February 12, 2016 at 2:49 pm #14070

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Wow that’s fantastic. So could you make a custom thermostat housing for example?

Yea I would think so, ABS would I reckon do it.

February 12, 2016 at 3:11 pm #14071

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Nothing in life is free Gary. Was tongue in cheek lol.

Took it that way buddy. But that’s exactly the kind of stuff I want to do once I get my head around achieving nice results. Seems its not quite as easy as just pressing print, but it is very very cool so its worth the playing around and time learning.

-

This reply was modified 8 years, 10 months ago by

VRSenator065.

VRSenator065.

February 12, 2016 at 3:51 pm #14078

pir4teParticipant- Mallala

- 640 HP hyper-cruising SS-V Flagonwagon

View build HERE

Posts: 154

Wow that’s fantastic. So could you make a custom thermostat housing for example?

Yea I would think so, ABS would I reckon do it.

Maybe, but I used to work with an ABS pipe and fitting company years ago and thought to built a remote filter adaptor but temp was borderline reliability issue.

So it it feasible to use 3D printing to create a thermostat (and heater plumbing) mold for manufacture in ceramic or alloy, or other material?

Naturally as-pirated, all-motor.

February 12, 2016 at 4:05 pm #14079

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

I don’t think with mine, commercial systems yes although not sure the cost. Sounds like you are talking about laser sintering, mine is plastic extruder style. I can use metal impregnated plastics, even wood impregnated that smells, sands and stain like wood.

This is what I can use on mine;

Supported Materials: ABS, PLA, HIPS, PVA, wood filled filaments, Polyester (Tritan), PETT, bronze and copper filled filaments, Polycarbonate, Nylon, PETG, conductive PLA and ABS, UV luminescent filaments, PCTPE, PC-ABS.

February 12, 2016 at 4:18 pm #14080

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Just researching, looks like Polycarbonate may be the go?

February 12, 2016 at 8:09 pm #14081So if I supply a Holden badge that is now NLA. Can you make an exact copy?

February 12, 2016 at 8:52 pm #14082

pir4teParticipant- Mallala

- 640 HP hyper-cruising SS-V Flagonwagon

View build HERE

Posts: 154

Gary, Davies Craig EWP uses “glass-filled nylon” is that polycarbonate, or maybe a material you could use?

Naturally as-pirated, all-motor.

February 12, 2016 at 9:17 pm #14083

exec24Participant- 2004 VY S2 Berlina 1996 VS 5L Sedan

View build HERE

Posts: 435

if your able to make a set……VR or VS Caprice Seat trims Would be good, impossible to find a good used set

-

This reply was modified 8 years, 10 months ago by

exec24.

exec24.

February 15, 2016 at 4:55 pm #14155

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Sorry, been in the shed and not on here that much

So if I supply a Holden badge that is now NLA. Can you make an exact copy?

.

Yep i think so, I am actually using the LsXcen one for IJ to try a few ideas of how to do it nicely, but yep that’s the idea.

Gary, Davies Craig EWP uses “glass-filled nylon” is that polycarbonate, or maybe a material you could use?

Not sure, general consensus on a 3D printing forum I am on is that it would be OK to prototype and test, but not for long term use. Having said that its seems another thing people do is use the 3D printed part to make a mold and get it down out of a decent material.

March 10, 2016 at 5:09 pm #14943Just saw this. It’s a fantastic idea. I’m sure there are plenty of guys on this forum who would be very happy for you to make test pieces for them. Personally I’d be happy paying for a prototype. At the end of the day something that is 1 or 2 % from being perfect is much better than nothing at all. I’m sure we all know the feeling of knowing exactly what we want/need, but not being able to find/buy it! And it looks like the small things you have done for your Senator have turned out just fine. Good luck with this!

-

AuthorPosts

You must be logged in to reply to this topic.